OUR PRODUCTS

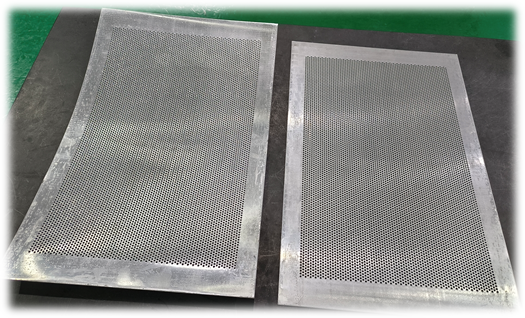

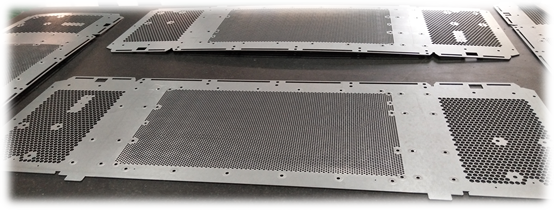

Sheet Metal Leveling Machine To Straighten Various Metal Plates & Improve The Flatness Of Sheet Metal

OUR SERVICE

Sheet Metal Leveling Machine To Straighten Various Metal Plates & Improve The Flatness Of Sheet Metal

WHO ARE WE

Guangdong Xinlijin Intelligent Equipment Co., Ltd. We are a premier leveling machine manufacturer which is located in Dongguan City, Guangdong Province, China. We specialize in sheet metal roller leveler machines including R&D, manufacturing and selling, our professional capabilities have enabled us to gain more and more customers in the domestic and international markets. We delight our customers on the promise to never compromise quality over price. Customers value our teamwork, expertise and passion for helping them succeed now and into the future.

Where is it applied & How does it work

WHY CHOOSE US

We focus on R&D, manufacturing and sales of sheet metal rolling machines, and our professional capabilities have enabled us to win more and more customers in domestic and international markets.

-

Experienced R&D And Engineering TeamOur R&D and engineering team has more than 20 years of experience in the sheet metal industry. We can provide the best solution for customers.

-

Professional Service TeamWe will respond to order inquiries within 24 hours.

-

A Quick DeliveryWe will have stock availability of most of standard models and keep some stock for critical components for providing a quick delivery date for any new orders for both standard one and customized one.

-

Our PurposeOur intension is to add value to all customers and metal industrial continuously.