Overview:

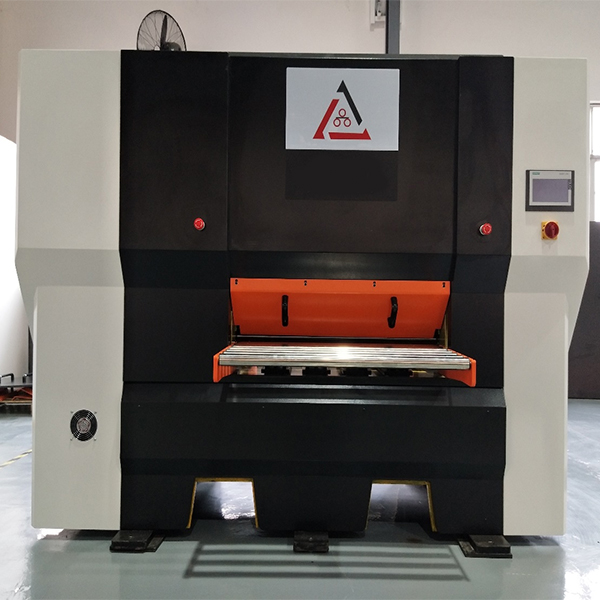

- 4-fold ( 4 - high) NC leveling machine (Metal Plate Leveler, Roller leveling machine, Roller Leveler)

- All kinds work-piece can be processed covering low carbon steel, Aluminum, copper, stainless steel, high tensile steel etc.

- Leveling capacity for 1.0 – 4.0mm thickness materials.

Features of roller leveling

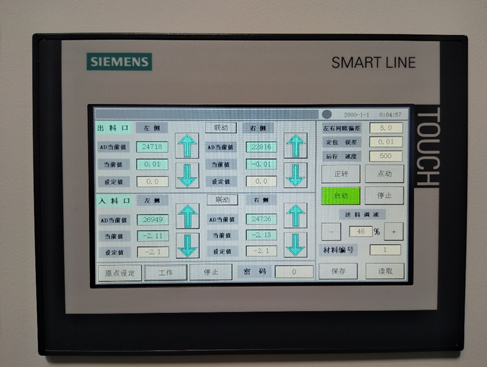

Intuitive touchscreen HMI

Gap control of leveling rollers

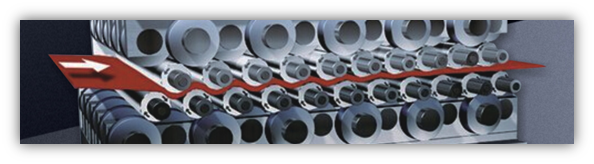

Equipment process principle

In the leveling process, the work piece passes through a series of alternating bends, during that process, the degree of bending is slowly weakened and finally flattened. we called that principle “Bauschinger effect”. The material is processing in such a way for releasing internal stress and getting a perfect flatness of work piece in final so that it’s ready for the coming production steps such as welding, bending or folding etc.

Equipment main feature

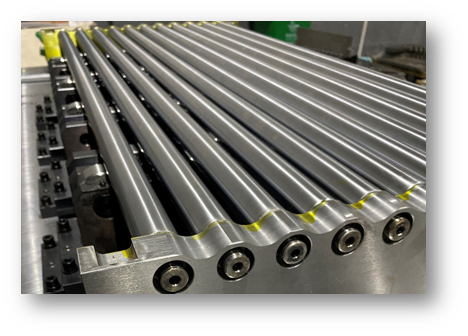

a) Machine is equipped with 21pcs×φ50mm leveling rollers in which 10pcs on the upper layer and 11 pcs on the lower layer. The leveling rollers went through finished quenching and tempering, precious machining, hard chrome plating, grinding etc. Surface hardness comes HRC60±2° (chrome layer thickness ≥0.1mm)

b) There are some support rollers columns uniformly distributed upper and lower for supporting leveling roller sets, making leveling rollers bears pressure in balance.

c) Main shaft bearings are shielded and sealed NSK bearing made in JAPAN with accuracy within 5μ, it can well reserve itself stocked lubrication oil and prevent dust enters.

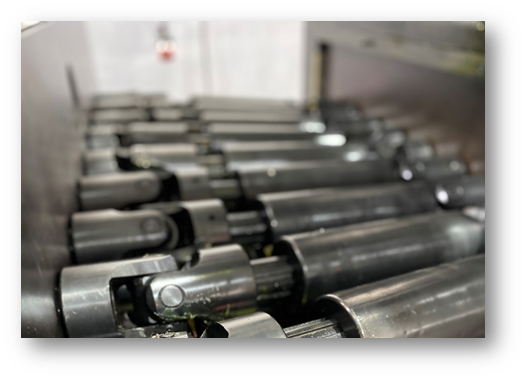

d) The power transmission system for the leveling rollers consist of motor, reducer, gearboxes and universal joints. Each leveling roller drove by one transmission shaft for achieving high transmission efficiency and angle compensation capability.

e) SIEMENS PLC, SIEMENS HMI, DELTA servo motor and DELTA servo driver are elements of our leveling roller gap control system. It makes the entire operation process simply and intelligent. What we ought to do is only set leveling data in HMI. And the language option can be customized.

|

Model |

XLJ50-400 |

XLJ50-600 |

XLJ50-800 |

XLJ50-1000 |

XLJ50-1300 |

XLJ50-1600 |

|

Material Max. width |

400mm |

600mm |

800mm |

1000mm |

1300mm |

1600mm |

|

Leveling capacity |

1.0-4.0mm |

|||||

|

Leveling roller diameter |

50mm |

|||||

|

Leveling roller quantity |

21pcs |

|||||

|

Shortest work-piece |

100mm |

|||||

|

Support roller columns |

two |

three |

four |

five |

six |

seven |

|

Leveling roller gap adjust method |

NC |

|||||

|

Leveling speed |

0-12m / min |

|||||

|

Voltage |

AC 3 Phase 380V 50HZ(Can customize) |

|||||

Add a review

Your email address will not be published. Required fields are marked *